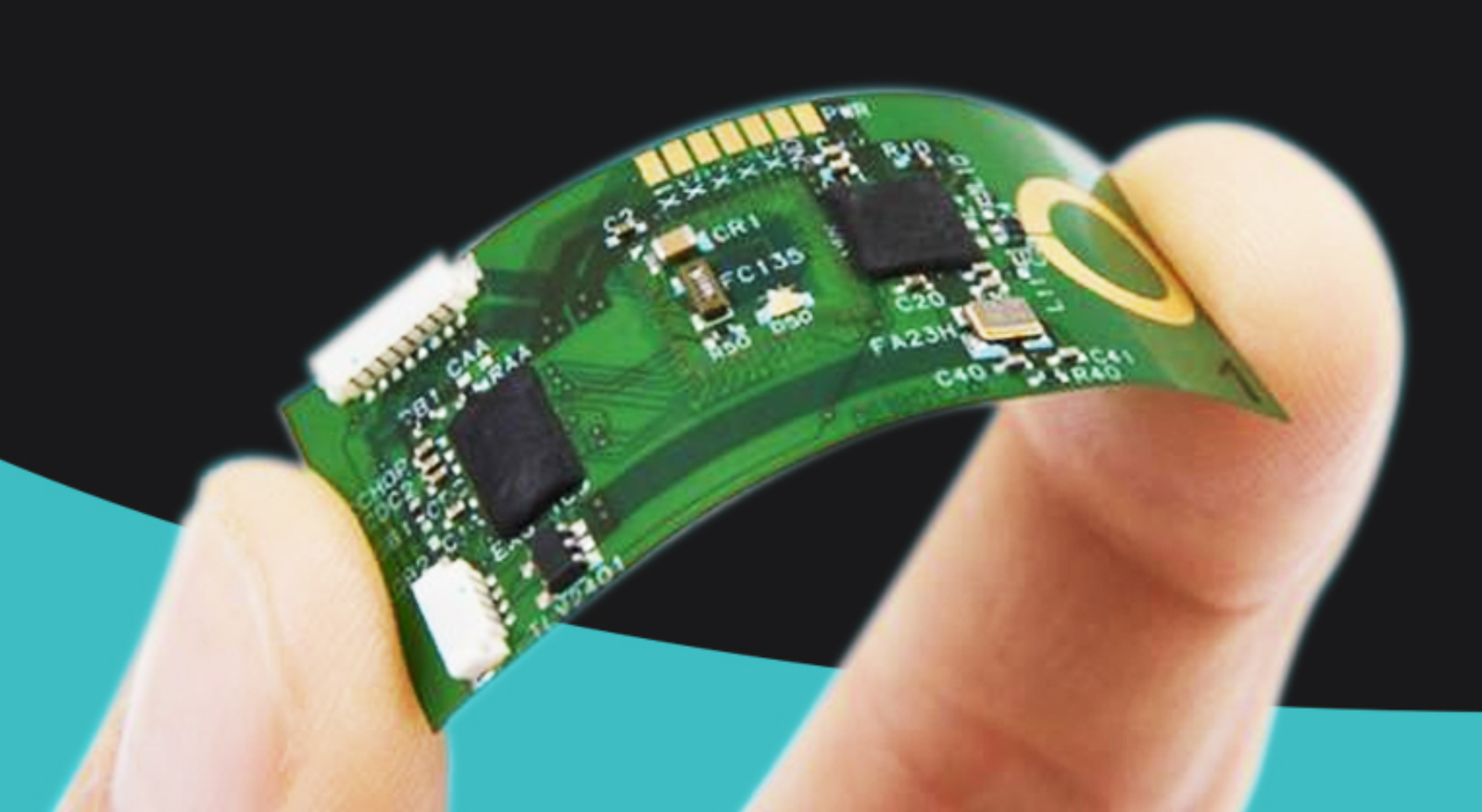

rinted Circuit Boards (Flexible PCBs) have gained prominence due to their versatility, adaptability, and efficiency in meeting the demands of modern electronic devices. However, the inherent flexibility that gives these boards their name and advantage also brings forth challenges in maintaining structural integrity and functionality in certain applications. This is where the concept of PCB stiffeners comes into play, serving as a critical component in the design and implementation of flexible PCBs. This article delves into the necessity of stiffeners in flexible PCBs, exploring their purposes, types, materials, and application techniques, thereby providing a comprehensive guide for professionals navigating the complexities of flexible PCB design and assembly.

Understanding Flexible PCBs and Their Applications

Flexible PCBs, as the name suggests, are designed to be flexible, allowing them to conform to different shapes and fit into spaces where traditional rigid PCBs cannot. This flexibility is achieved through the use of materials like polyimide or polyester film, which are both flexible and durable. The applications of flexible PCBs are vast, ranging from simple devices like digital watches to complex machinery such as satellite communication systems. The flexibility offers significant advantages in reducing weight, saving space, and enhancing the durability of devices, especially those subject to bending and flexing during their operation.

The Role of Stiffeners in Flexible PCBs

Despite the benefits, the flexibility of these PCBs can sometimes be a double-edged sword. Areas of the PCB that require a certain degree of rigidity, either to support component weight or to ensure connector stability, can pose a challenge. This is where stiffeners are employed; they are not active electrical components but rather serve as mechanical support elements that are added to specific areas of the flexible PCB to provide the necessary rigidity and stability for the mounted components or connectors.

l Providing Structural Integrity Where Needed

Flexible PCBs are inherently designed to be just that—flexible. This flexibility allows them to be used in innovative ways, fitting into spaces and shapes that rigid PCBs cannot accommodate. However, this flexibility also means that certain parts of the PCB may require additional support to function correctly, especially areas that bear the weight of mounted components or those that need to maintain a connection with other parts of the device. Stiffeners are strategically placed to provide this support, essentially acting as the backbone in specific areas of the PCB.

l Facilitating Component Mounting and Assembly

In the world of electronic devices, miniaturization continues to push the boundaries of how small and efficiently components can be assembled. Flexible PCBs are at the forefront of this trend, enabling the creation of devices that are not only smaller but also more complex in their functionality. However, the assembly of components on such PCBs, particularly through Surface Mount Technology (SMT) and Plated Through-Hole (PTH) techniques, requires precise mechanical stability. Stiffeners ensure that despite the overall flexibility of the board, these critical areas remain rigid enough to securely hold components in place, reducing the risk of failure due to mechanical stress.

l Enhancing Connector Functionality

Connectors, particularly Zero Insertion Force (ZIF) connectors, are vital for the functionality of many electronic devices, enabling easy assembly and maintenance. However, the insertion and operation of these connectors necessitate a precise fit, which can only be achieved if the PCB has the correct thickness and rigidity in the relevant areas. Stiffeners play a crucial role in achieving these specifications, ensuring that connectors function reliably over the lifespan of the device.

l Balancing Flexibility and Rigidity

The art of using stiffeners in flexible PCB design lies in striking the perfect balance between maintaining the board’s inherent flexibility and providing necessary rigidity. This balance is crucial not only for the physical assembly of the board into the final product but also for the board’s functionality throughout its operational life. Areas that need to flex during use must remain unimpeded, while those that require stability to protect components or ensure connectivity must be adequately supported. Achieving this balance requires a deep understanding of the mechanical stresses that the PCB will encounter in its end-use environment.

Types and Purposes of PCB Stiffeners

l Mechanical Support for Components

One of the primary roles of stiffeners is to provide a solid foundation for Surface Mount Technology (SMT) and Plated Through-Hole (PTH) components, ensuring that these components remain stable and secure, especially in areas subjected to mechanical stress or frequent handling.

l Thickness Management and ZIF Connector Compatibility

Stiffeners also play a crucial role in maintaining the overall thickness of flexible circuits, especially for applications requiring Zero Insertion Force (ZIF) connectors. The precise thickness is crucial for the proper fit and function of these connectors.

l Enhanced Durability

By restricting the flexibility of certain areas, stiffeners can prevent excessive bending that might otherwise lead to material fatigue or failure, thereby enhancing the durability of the flexible PCB.

Materials for PCB Stiffeners

Selecting the appropriate material for stiffeners is vital to the success of the PCB design. Common materials include FR4, a glass fiber epoxy laminate known for its rigidity and thermal resistance, and polyimide, noted for its flexibility and high temperature tolerance. The choice of material depends on the specific requirements of the application, including thermal management, mechanical stability, and cost considerations.

Application Techniques

The application of stiffeners to flexible PCBs requires precision and care. Techniques vary depending on the stiffener material and the design of the PCB but generally include thermal bonding or the use of adhesive. The process must ensure a secure bond without compromising the integrity of the PCB or the functionality of the components.

Design Considerations and Challenges

Incorporating stiffeners into flexible PCB designs introduces a set of considerations and challenges, from ensuring the right balance between flexibility and rigidity to managing the thickness and weight of the board. Designers must carefully plan the placement and size of stiffeners, taking into account the assembly process and the final application of the PCB.

Conclusion

Stiffeners are indispensable in the design and implementation of flexible PCBs, providing the necessary mechanical support to ensure the reliability and functionality of modern electronic devices. Their correct selection and application are critical to achieving the desired balance between the inherent flexibility of the PCB and the structural integrity required for specific components and connectors. As the applications for flexible PCBs continue to expand, the role of stiffeners will undoubtedly grow in importance, underscoring the need for ongoing research, development, and innovation in this field.

Through a deeper understanding of the necessity, types, materials, and application techniques of stiffeners, professionals in the electronics industry can navigate the complexities of flexible PCB design and assembly with greater confidence and expertise. This knowledge not only enhances the reliability and performance of electronic devices but also opens up new possibilities for innovation and design excellence in the world of flexible electronics.

The Importance of Choosing the Right Manufacturing Partner

When venturing into the realm of flexible PCB development, the selection of a manufacturing partner becomes a pivotal decision that can significantly impact the quality, reliability, and efficiency of your electronic products. A trusted flex PCB manufacturer like Arisentec not only provides expert PCB design services but also specializes in turnkey PCB assembly, which encompasses everything from quick turn PCB prototypes to full-scale PCBA manufacturing. This integrated approach ensures that every aspect of the PCB, including the precise application of stiffeners, is managed with the utmost expertise and attention to detail.

The best PCB manufacturers in China, such as Arisentec, have established a reputation for excellence by consistently delivering high-quality products tailored to the unique needs of their clients. Whether it’s a simple prototype or a complex printed circuit board assembly project, these manufacturers leverage their extensive experience and state-of-the-art technology to provide solutions that meet the highest standards of quality and performance.

Furthermore, the ability to offer comprehensive services, from PCB assembly to PCBA manufacture, under one roof can drastically streamline the production process, reducing time-to-market and minimizing the potential for errors. This turnkey solution is particularly beneficial for projects requiring quick turn PCB prototypes, where speed and accuracy are of the essence. By partnering with a manufacturer that excels in both pcb design services and PCB assembly, clients can enjoy a seamless, efficient, and cost-effective path from concept to completion.

In summary, the collaboration with a distinguished flex PCB manufacturer like Arisentec not only enhances the quality and performance of your flexible PCBs but also ensures a smooth, swift, and successful transition from design to final product, making it an invaluable component of any electronic device project.

Why Does Flexible PCB Need Stiffeners?

rinted Circuit Boards (Flexible PCBs) have gained prominence due to their versatility, adaptability, and efficiency in meeting the demands of modern electronic devices. However, the inherent flexibility that gives these boards their name and advantage also brings forth challenges in maintaining structural integrity and functionality in certain applications. This is where the concept of PCB…