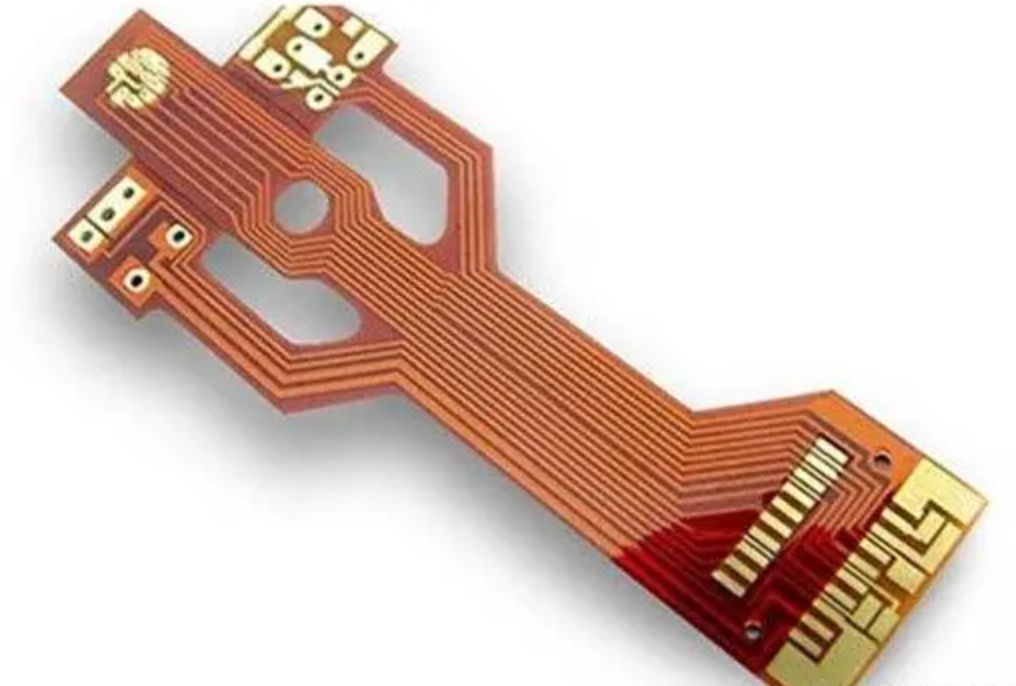

In the fast-paced and innovative world of electronics, flexible printed circuit boards (PCBs) are a cornerstone of modern design, providing the flexibility necessary for the latest devices. These boards are crucial in enabling more creative and compact product configurations, capable of bending and folding to fit seamlessly into small and dynamically changing electronic gadgets. Yet, the inherent flexibility of these boards introduces unique challenges that often necessitate the use of stiffeners. This article delves deeper into the importance of stiffeners in flexible PCB applications, highlighting their critical role and the nuances of their implementation.

Understanding Flexible PCBs

Flexible PCBs, commonly referred to as flex circuits, are not just innovative; they are vital in the contemporary landscape of electronics. Manufactured from pliable materials such as polyimide or polyester films, these boards are designed to flex, conforming to the tiniest and most irregular spaces in devices such as smartphones, wearable technology, and advanced medical instruments. Unlike traditional rigid PCBs, which are constructed on stiff, unyielding substrates, flex circuits cater to the sophisticated requirements of electronic assemblies where minimizing space usage and maximizing form factor are crucial.

The Crucial Role of Stiffeners

The advantages of flexible PCBs are significant in modern electronic design, but without appropriate structural enhancements, their application can lead to several issues that compromise both their functionality and durability. Here’s an expanded look at why stiffeners are indispensable in these applications:

- Structural Support for Components: The mounting of inherently rigid electronic components like capacitors, integrated circuits, and connectors can exert considerable stress on the flexible substrate. Without stiffeners, the substrate could deform or even break under the weight and operational forces of these components. Stiffeners act as a crucial mechanical backbone, distributing the load and preserving the integrity of the flex circuit at component mounting points.

- Mechanical Durability: Flex circuits are often integral to devices that require bending during assembly and use. Areas around connectors or other engagement points are particularly susceptible to wear and fatigue from repetitive mechanical stress. Stiffeners provide essential reinforcement at these critical points, ensuring the flex circuit can endure insertion forces and flexing without damage, thus significantly extending the life of the product.

- Improved Heat Dissipation: High-performance electronic components generate considerable heat during operation, which can degrade the performance and lifespan of the flexible materials used in PCBs. Stiffeners made from thermally conductive materials, such as aluminum, help spread this heat more evenly across the board, mitigating hotspots and protecting sensitive components from thermal damage. This feature is particularly crucial in compact devices where effective thermal management is key to maintaining overall device integrity and performance.

- Facilitating Reliable Connections: Mechanical connections, such as those involving Zero Insertion Force (ZIF) connectors, require precise mechanical features to function reliably. Stiffeners provide the necessary rigidity to maintain the dimensional accuracy of these features, ensuring that connectors engage and disengage smoothly without placing undue stress on the flexible parts of the PCB. This reliability is vital in critical applications, such as in medical devices or military electronics.

- Enhancing Flexibility: The use of stiffeners is a delicate balance between adding necessary rigidity and maintaining the intrinsic flexibility of the PCB. By selectively reinforcing areas that need to withstand mechanical or thermal stress, the rest of the PCB can remain as flexible as needed. This selective stiffening allows for the design of highly dynamic and mechanically complex devices that can perform reliably under a range of operational conditions.

Design Considerations with Stiffeners

The integration of stiffeners into a flexible PCB requires careful design and engineering to ensure that they enhance functionality without undermining the board’s inherent flexibility. Key considerations include ensuring material compatibility to avoid issues like delamination, selecting the optimal thickness for stiffeners to provide adequate rigidity without overly increasing the assembly’s overall thickness, and strategically placing stiffeners to minimize their impact on the PCB’s flexibility.

Types of Stiffeners and Their Materials

Selecting the appropriate stiffener material is critical, depending on the specific requirements of the application:

– **FR-4:** Widely used for its mechanical stability and good thermal resistance, making it suitable for general applications where additional rigidity is necessary.

– **Polyimide (PI):** Selected for its excellent thermal stability, ideal for high-temperature environments.

– **Aluminum:** Preferred for its superior thermal conductivity, ideal for applications that require effective heat dissipation.

**Design and Implementation Strategies**

Effective design and implementation of stiffeners in flexible PCBs involve several strategic decisions:

– **Strategic Placement:** Stiffeners should be strategically positioned to support critical areas without compromising the flexibility required in other parts of the PCB.

– **Size Optimization:** The dimensions of the stiffeners should be carefully calculated to provide necessary support without an undue increase in thickness or weight.

– **Attachment Techniques:** Depending on the application, stiffeners can be bonded with adhesives or mechanically fastened to the flex circuit, with each technique impacting the overall reliability

and performance of the assembly.

Conclusion

Stiffeners are essential in the design and application of flexible PCBs, offering vital support where needed while allowing the circuits to maintain their inherent flexibility. As technology progresses, the role of flexible PCBs and their stiffeners in electronics will only increase, enabling the creation of more sophisticated and compact device designs. This careful balancing of flexibility and rigidity is what makes stiffeners indispensable in the realm of modern electronics.

For those looking to engage with a leading provider of these technologies, consider Arisen Technology PCB , renowned for being among the best PCB manufacturers in China. Specializing in PCB design services, PCBA manufacturing, quick turn PCB prototypes, and turnkey PCB assembly, Arisen Technology PCB excels in delivering high-quality solutions tailored to client needs. Whether you need fast PCB prototyping service, microcontroller PCB design, or comprehensive printed circuit board assembly, Arisen Technology PCB offers expertise and quality that can help bring your most challenging PCB board projects to fruition.

What is a Flex PCB Stiffener?

In the fast-paced and innovative world of electronics, flexible printed circuit boards (PCBs) are a cornerstone of modern design, providing the flexibility necessary for the latest devices. These boards are crucial in enabling more creative and compact product configurations, capable of bending and folding to fit seamlessly into small and dynamically changing electronic gadgets. Yet,…