In PCB fabrication, the transition from a digital design to a physical product involves several crucial steps. One of the most important phases in this process is the preparation and submission of the correct files. These files contain all the necessary information for manufacturing the printed circuit board to precise specifications. Below is an overview of the key files required for successful PCB fabrication, as handled by ArisenTec.

1. Files

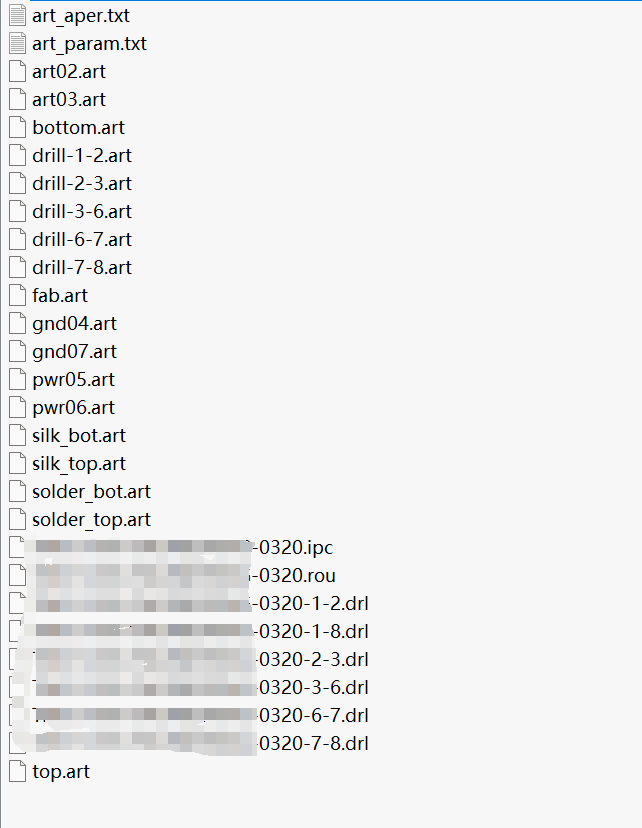

Gerber files are the most critical files for PCB fabrication. They serve as the standard format for conveying design information, including the copper layers, solder mask, and silkscreen layers. Each layer of the PCB has its corresponding Gerber file. For instance, one file might contain the top copper layer, while another includes the bottom solder mask. At ArisenTec, we ensure that these files are meticulously reviewed and optimized, enabling our PCBA manufacturing process to accurately translate the design into a physical circuit board.

2. Drill Files

Drill files provide information about the locations and sizes of holes on the PCB. These holes may be used for vias, through-hole components, or mounting purposes. The most common format for drill files is Excellon, which is widely supported by PCB factories like ArisenTec. Accurate drill files are essential, as they ensure that holes are correctly placed and sized, preventing misalignment and structural weaknesses.

3. Bill of Materials (BOM)

The Bill of Materials (BOM) is a comprehensive list of all components required to assemble the PCB. It includes part numbers, descriptions, quantities, and sometimes additional details like supplier information. A well-prepared BOM is crucial for both PCB assembly costs and efficiency.

4. Pick and Place Files

Pick and Place files, also known as Centroid files, are used to automate the placement of surface-mount components on the PCB. These files include the X and Y coordinates, rotation, and reference designators for each component. Accurate Pick and Place files are key to reducing assembly errors.

5. Netlist File

A Netlist file outlines the electrical connections between components on the PCB. This file is used to verify that the physical layout matches the intended design, ensuring that all electrical connections are correctly established. At

6. Assembly Drawings

Assembly drawings provide visual guidance for placing components on the PCB. These drawings are particularly important for complex boards, where the correct orientation and placement of components are critical.

7. Fab Drawings

Fabrication drawings include mechanical details necessary for manufacturing the PCB, such as dimensions, hole sizes, board thickness, and material specifications. These drawings also indicate any special requirements, like cutouts or slots, that are not covered in the Gerber files. ArisenTec uses these drawings to ensure that the PCB stiffener and other physical features meet design specifications.

8. Test and Inspection Files

Test and inspection files, such as Automated Optical Inspection (AOI) data or test point locations, are used during the quality control phase of PCB fabrication.

Conclusion

In summary, successful PCB fabrication at ArisenTec depends on the accurate preparation and submission of various files. Gerber files, drill files, BOMs, Pick and Place files, Netlists, assembly drawings, fab drawings, and test files all play critical roles in transforming a digital design into a reliable, high-quality printed circuit board. Ensuring these files are correctly formatted and free of errors is essential for minimizing PCB assembly costs and achieving optimal results in the manufacturing process. By partnering with ArisenTec, designers can ensure that their designs are brought to life with precision, efficiency, and the highest quality standards.

Choosing the Right Wires for Breadboard Wiring: A Comprehensive Guide

Breadboards are a staple in electronic circuit building, offering flexibility and ease of use for both beginners and professionals. However, one of the most critical aspects of working with breadboards is selecting the right wires. The wires you choose can impact not only the functionality of your circuit but also its longevity and ease of…

How to Improve Heat Dissipation in PCB Design

Introduction As modern electronic devices become more complex and power-dense, heat dissipation has emerged as a critical factor that directly impacts device performance and reliability. Excessive junction temperatures in electronic systems can shorten the lifespan of components and lead to system failure. Thus, optimizing the PCB (Printed Circuit Board) design to improve heat dissipation is…

Manufacturing Process of Multilayer PCBs

Multilayer PCB manufacturing methods include the plated-through hole (PTH) and high-density interconnect (HDI) methods, both achieved by combining different processes to realize the circuit board structure. Currently, the most widely used method is the PTH method, which has been developed and refined over more than half a century. The PTH method is mature in terms…