In the realm of PCB manufacturing, the solder mask is an essential feature that significantly impacts the performance and longevity of printed circuit boards (PCBs). This protective layer covers the copper traces on the PCB, leaving only the areas meant for soldering exposed. Typically, solder masks are green, but they can also come in other colors such as red, blue, and black, depending on the specific requirements.

Functionality and Importance of Solder Mask

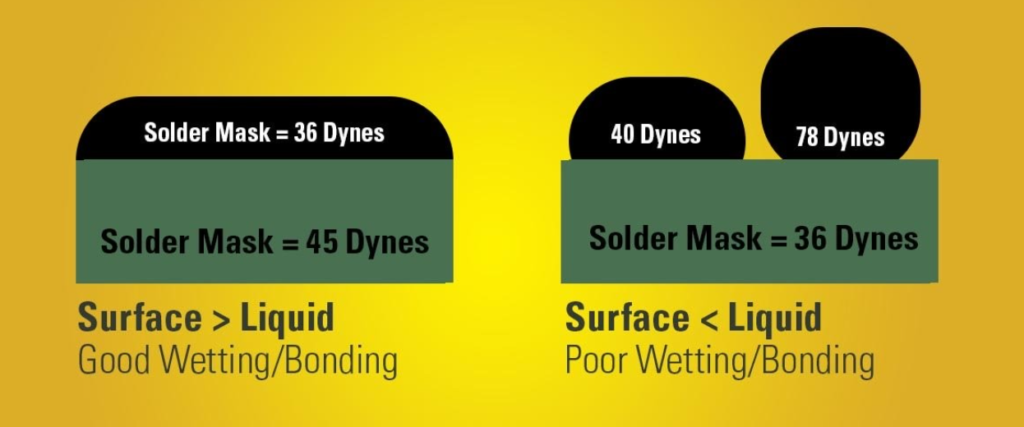

The primary purpose of the solder mask is to prevent solder bridges from forming between closely spaced solder pads during the soldering process. These bridges could cause short circuits, leading to potential malfunctions or damage to the electronic components. By applying the solder mask, manufacturers ensure that solder adheres only to the designated pads, facilitating clean and precise connections.

Additionally, the solder mask acts as a barrier against environmental factors like moisture, dust, and chemicals, which could cause oxidation and corrosion of the copper traces. This protection is crucial for extending the lifespan of the PCB, particularly in industries where reliability is paramount, such as automotive, aerospace, and consumer electronics.

Types of Solder Masks Used by ArisenTec

At ArisenTec, a leading PCBA manufacturer, we utilize various types of solder masks to meet the specific needs of our clients:

1. LPI (Liquid Photoimageable) Solder Mask: This is the most commonly used type, applied as a liquid and then cured through a photolithographic process. It offers high precision, making it ideal for fine-pitch components and high-density PCB designs.

2. Dry Film Solder Mask: This type is a solid film that is applied to the PCB and then developed using UV light. It is particularly useful for applications requiring a thicker mask layer, though it is less commonly used than LPI.

3. Epoxy Liquid Solder Mask: Known for its cost-effectiveness, this type is typically used in simpler PCB designs. While it doesn’t offer the same level of precision as LPI, it is a viable option for certain applications.

Solder Mask in Advanced PCB Applications

In complex PCB designs, such as those involving stiffener flex PCBs or flex circuit stiffeners, the solder mask must be carefully selected and applied to accommodate the flexible nature of the materials. ArisenTec ensures that the solder mask does not crack or peel during flexing, maintaining the integrity of the PCB over time. As PCBs continue to evolve, shrinking in size while increasing in functionality, the precision required in solder mask application grows, driving advancements in both materials and processes.

Conclusion

The solder mask is a critical component in the PCBA manufacturing process, providing necessary protection and ensuring reliable soldering. At ArisenTec, we understand the importance of using the right solder mask for each project to prevent short circuits, protect against environmental damage, and meet the high precision demands of modern electronic devices. Our commitment to quality and innovation allows us to deliver PCBs that meet the stringent requirements of our clients, ensuring the highest level of performance and durability.

Choosing the Right Wires for Breadboard Wiring: A Comprehensive Guide

Breadboards are a staple in electronic circuit building, offering flexibility and ease of use for both beginners and professionals. However, one of the most critical aspects of working with breadboards is selecting the right wires. The wires you choose can impact not only the functionality of your circuit but also its longevity and ease of…

How to Improve Heat Dissipation in PCB Design

Introduction As modern electronic devices become more complex and power-dense, heat dissipation has emerged as a critical factor that directly impacts device performance and reliability. Excessive junction temperatures in electronic systems can shorten the lifespan of components and lead to system failure. Thus, optimizing the PCB (Printed Circuit Board) design to improve heat dissipation is…

Manufacturing Process of Multilayer PCBs

Multilayer PCB manufacturing methods include the plated-through hole (PTH) and high-density interconnect (HDI) methods, both achieved by combining different processes to realize the circuit board structure. Currently, the most widely used method is the PTH method, which has been developed and refined over more than half a century. The PTH method is mature in terms…