Introduction

The quest for efficient heat management in Printed Circuit Board (PCB) design is more crucial than ever in the rapidly evolving landscape of electronics. As devices become more powerful and compact, the heat they generate increases, posing significant challenges for PCB designers. Excessive heat can lead to reduced performance, reliability issues, and even premature failure of electronic components. This article is dedicated to exploring innovative and effective strategies for improving heat dissipation in PCB designs. We will discuss various techniques ranging from material selection to layout optimization, each playing a pivotal role in enhancing the thermal performance of PCBs.

In this journey towards mastering heat dissipation in PCBs, we shall delve into the intricacies of various design elements. Each strategy discussed not only serves the purpose of reducing heat but also contributes to the overall efficiency and longevity of electronic devices. By the end of this article, readers will be equipped with a deeper understanding of how to tackle the thermal challenges in PCB design, ensuring their electronic devices operate at optimum temperatures and deliver sustained performance over time.

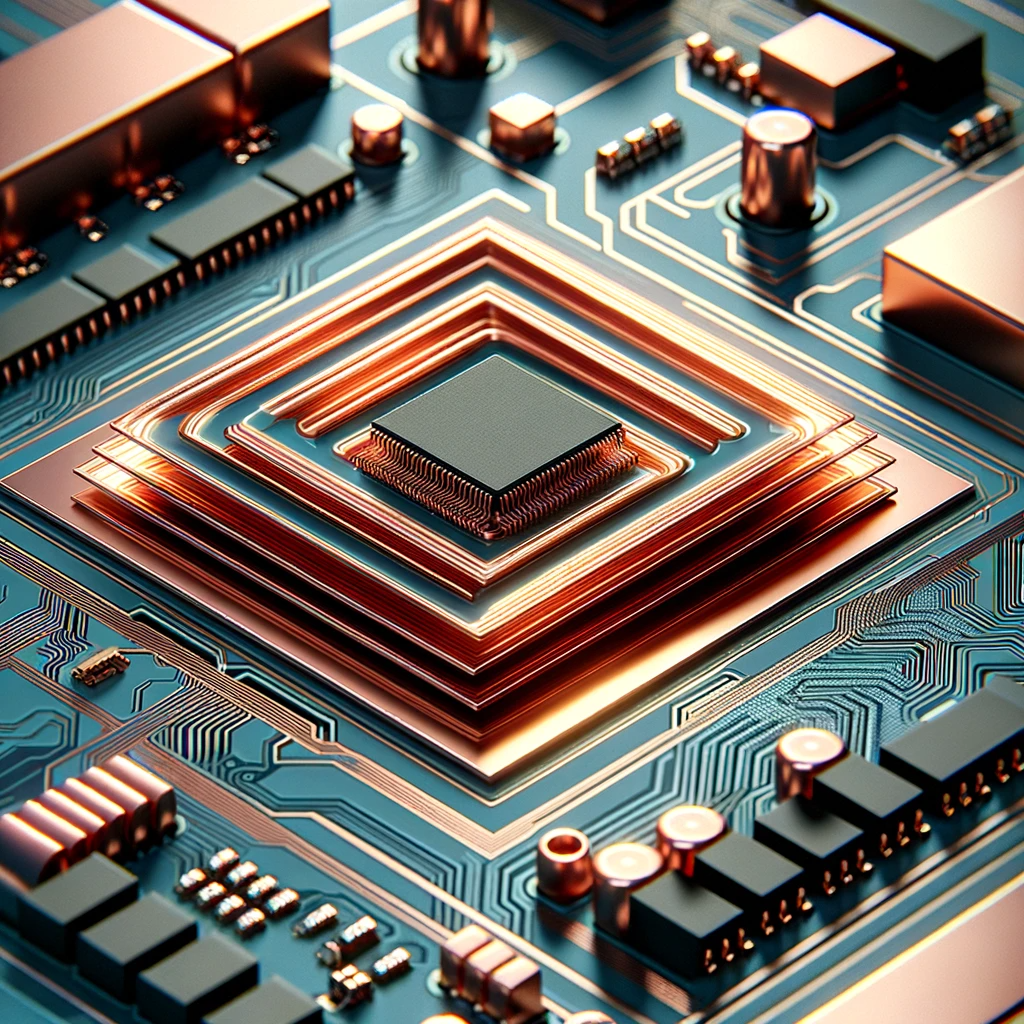

Adding Copper Foil

Copper foil is an integral component in PCB design, particularly for its role in managing heat. Its high thermal conductivity makes it an excellent choice for dissipating heat efficiently across the PCB. When used in areas with significant power supply, copper foil acts as a thermal conductor, spreading the heat generated by electronic components across the board. This spread helps in maintaining a uniform temperature, preventing the formation of hot spots which can be detrimental to the PCB’s performance and longevity.

The application of copper foil in PCB design is not just theoretical but is backed by practical successes in various high-tech industries. For instance, in high-performance computing where there is a significant generation of heat, the use of copper foil has proven to be effective in maintaining optimal operating temperatures. Similarly, in power electronics, where managing heat is crucial for maintaining efficiency and reliability, copper foil plays a vital role. These real-world examples underline the importance of incorporating copper foil in PCB designs to enhance heat dissipation.

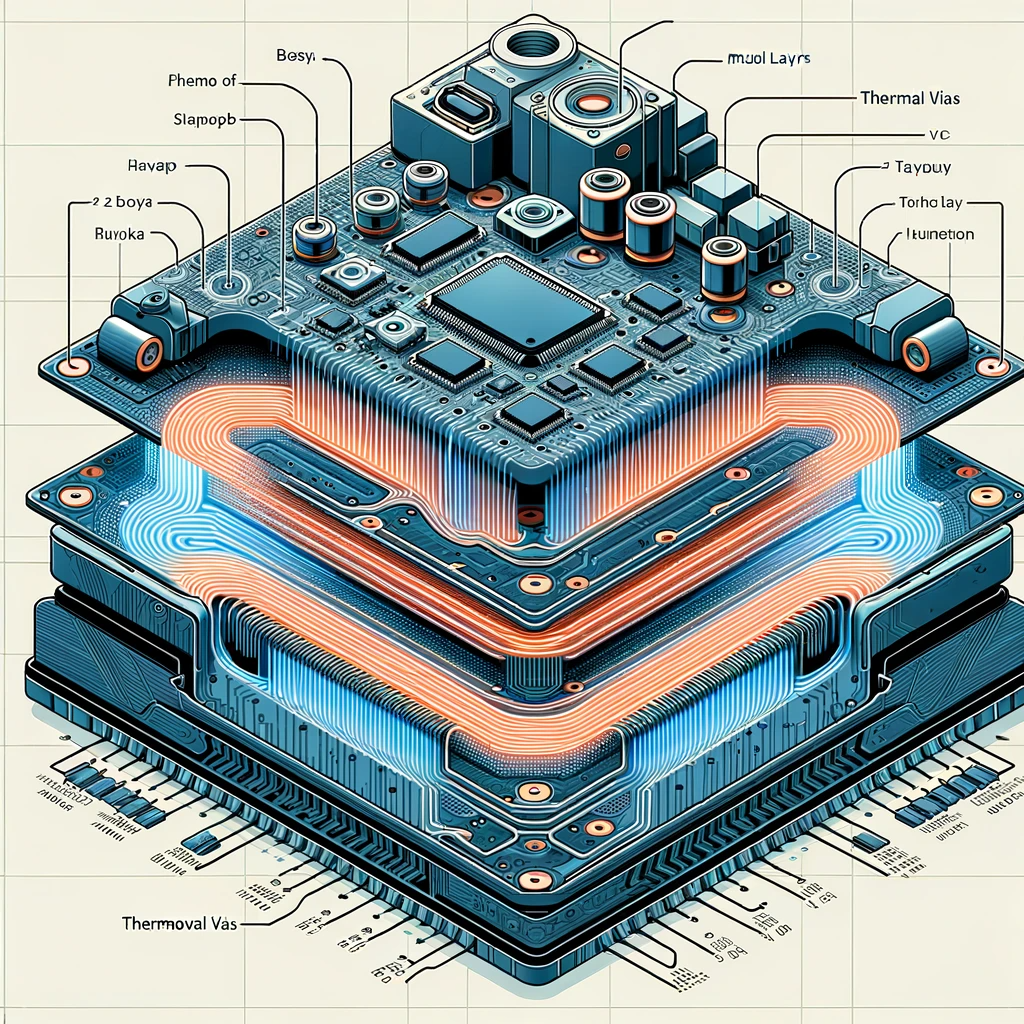

Using Thermal Vias

Thermal vias are small but mighty components in the realm of PCB thermal management. These are essentially conduits made within the PCB layers, filled or plated with a material that has high thermal conductivity. Their primary function is to facilitate the transfer of heat from one side of the PCB to the other, thereby aiding in reducing the overall temperature of the device. This is especially beneficial in high-density PCBs where removing heat from compact spaces is challenging.

Studies and practical applications of thermal vias have shown a significant improvement in the thermal performance of PCBs. By effectively lowering the device junction temperatures, thermal vias contribute to a more uniform thermal distribution across the board. This uniformity is crucial for the reliability and efficiency of electronic devices. Data from research in this field provides a compelling case for the inclusion of thermal vias in PCB design services as a standard practice for enhanced heat management.

Exposing Copper on the IC Back

The concept of exposing copper on the back of the Integrated Circuit (IC) is an innovative approach in thermal management in PCB design. This technique revolves around the principle of reducing thermal resistance between the copper surface and the air. By exposing the copper, heat is more efficiently transferred from the IC to the surrounding environment. This direct path for heat dissipation is particularly important in high-power applications where managing internal temperatures is critical for device stability and performance.

Design considerations for this technique are crucial and involve determining the optimal thickness of the copper layer and the surface area to be exposed. The effectiveness of this method has been observed in various applications, particularly where thermal challenges are significant. By implementing this approach, PCB designers can significantly enhance the heat dissipation capabilities of their designs, contributing to better thermal management and overall device performance.

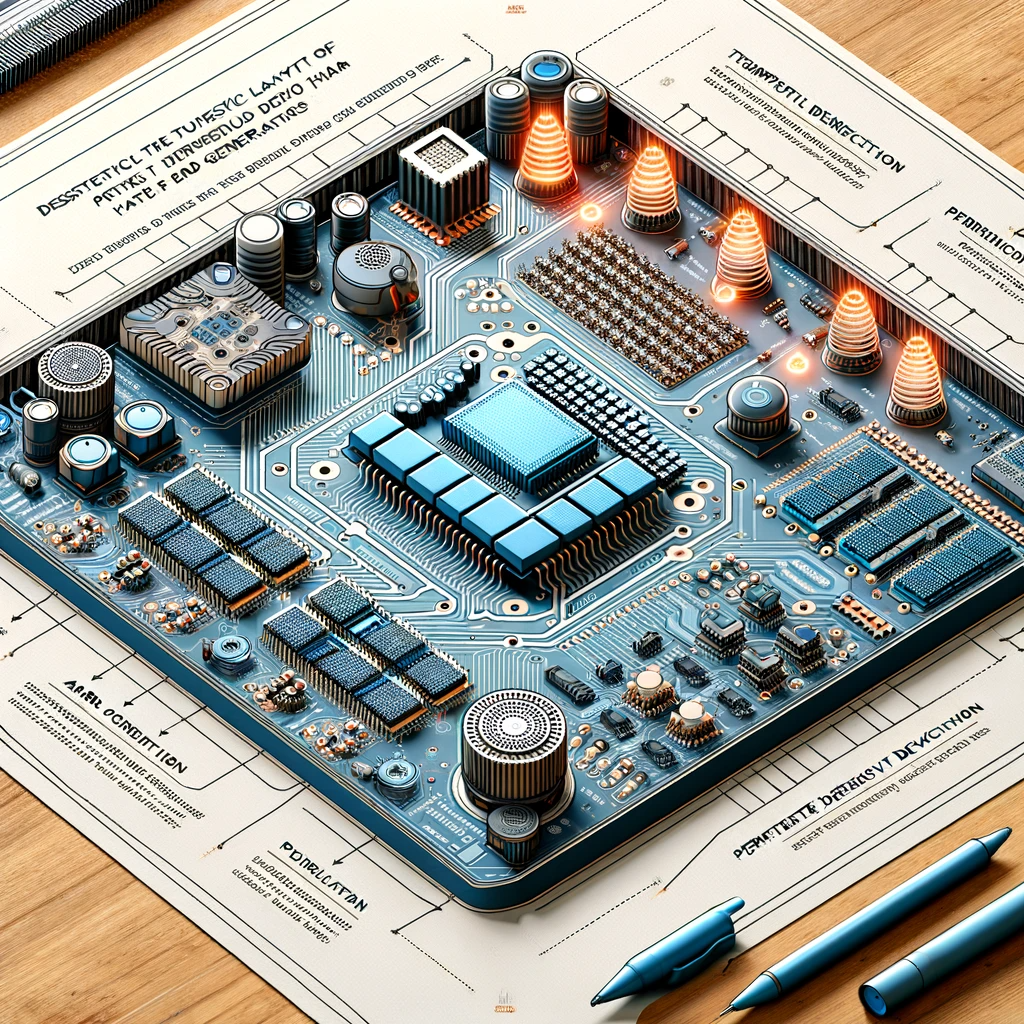

Strategic PCB Layout

The layout of components on a PCB plays a crucial role in thermal management. Strategic placement of thermally sensitive devices is essential. These devices should be located in cooler areas of the board to avoid heat-related damage or malfunction. Additionally, the configuration of temperature detection devices must be considered to ensure accurate monitoring of the PCB’s temperature. This placement helps in making informed decisions about heat management throughout the PCB.

The layout also involves the careful partitioning of devices based on their heat generation and dissipation characteristics. High-power devices, for instance, should be positioned in a way that facilitates efficient heat dissipation. Airflow around these devices is another critical factor; ensuring good airflow helps in the removal of heat from the PCB. Furthermore, the arrangement of temperature-sensitive and high-heat generation devices should be planned meticulously. This planning minimizes the thermal impact on sensitive components and contributes to the overall thermal efficiency of the PCB. By adhering to these guidelines, PCB designers can create designs that not only manage heat effectively but also enhance the overall performance and reliability of the pcb board projects.

Conclusion

In conclusion, effective heat dissipation is a cornerstone of successful PCB design, a principle strongly echoed by the ethos of Arisen Technology. The strategies discussed in this article, from adding copper foil to strategic PCB layout, are not only essential for managing the thermal challenges in modern electronics but also align with the innovative solutions provided by Arisen Technology. As we delve into the intricate world of PCB design, it becomes increasingly clear that the application of these techniques is vital for ensuring the longevity, reliability, and efficiency of electronic devices. Arisen Technology, with its commitment to quality and innovation in PCB design and manufacturing, stands as an exemplary model in incorporating these advanced heat management strategies. By embracing these approaches, designers and pcb manufacturer china alike can overcome thermal challenges, paving the way for the next generation of high-performing, durable electronic devices. This synthesis of cutting-edge design principles with practical industry insights is what sets Arisen Technolog