In the world of electronics, the programming of circuit boards is a critical phase that bridges the gap between hardware design and functional devices. Programming a circuit board involves transferring a set of instructions or software onto the hardware to control how it operates. This article provides an insight into the process, focusing on the role of PCB (Printed Circuit Board) manufacturers and assemblers in this intricate task.

The Role of PCB Manufacturers in Programming

Best PCB manufacturers, particularly those in China known for their manufacturing prowess, have streamlined the process of creating circuit boards that are ready for programming. These manufacturers, including flex PCB manufacturers, provide the physical platform – the PCB – which will later house the software. The PCB is designed to connect various electronic components, including microcontrollers, which are the primary elements programmed to perform specific tasks.

PCB Design Services

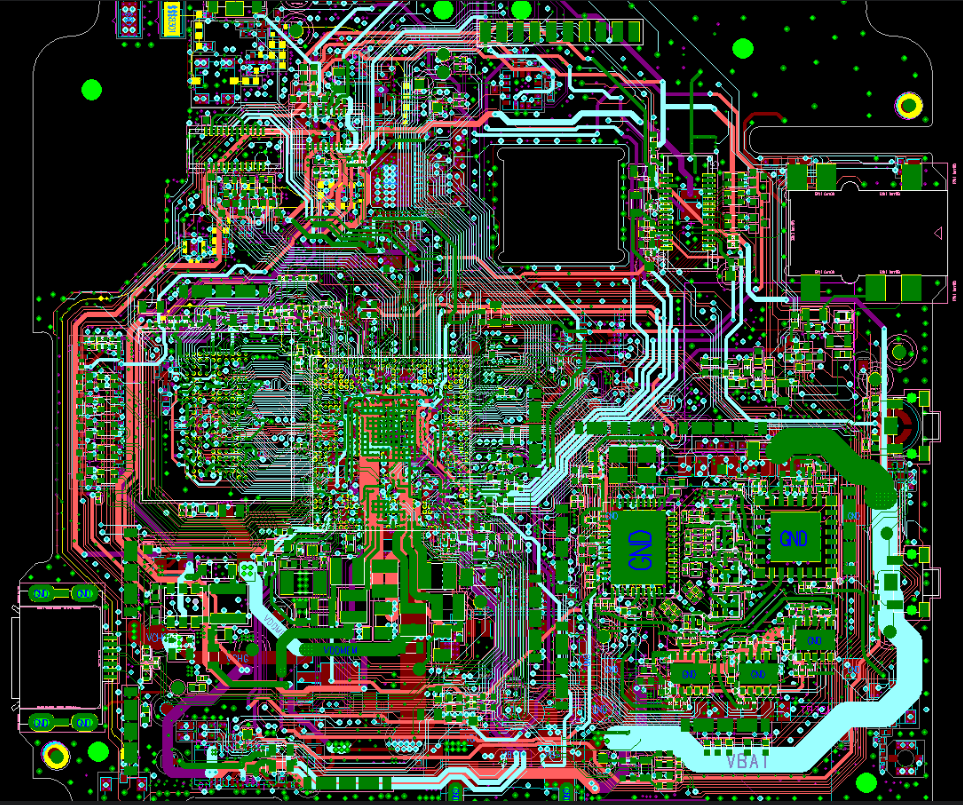

Before a PCB can be programmed, it must be meticulously designed. PCB design services play a crucial role in ensuring that the board meets the necessary specifications for the intended application. This includes creating a layout that accommodates all the electronic components and provides the necessary connectivity for programming and operation.

Microcontroller PCB Design

Microcontrollers are often at the heart of programmable PCBs. A microcontroller PCB design integrates a small computer on a single integrated circuit containing a processor core, memory, and programmable input/output peripherals. Programming these devices involves writing code, usually in languages such as C or C++, and loading it onto the microcontroller through various means, such as a serial interface or wireless bootloader.

PCB Assembly and PCBA Manufacturing

Once the PCB design is finalized, the assembly process begins. PCB assembly (PCBA) is the process of soldering or placing electronic components onto the PCB. PCBA manufacturing is a sophisticated process that involves both automated and manual steps to ensure precision and reliability. Turnkey PCB assembly services streamline the process by handling everything from component sourcing to final assembly, making it easier for clients to receive fully assembled boards ready for programming.

Printed Circuit Board Assembly

The printed circuit board assembly is the stage where components like microcontrollers, memory chips, and connectors are mounted onto the board. For the programming phase, it’s crucial that the assembly is done with precision to avoid any hardware issues that could interfere with the software upload.

Programming the Circuit Board

Programming a circuit board typically involves the following steps:

1. Code Compilation: The source code written for the microcontroller is compiled into a binary file, which the microcontroller can execute.

2. Connection: The PCB is connected to a programming device or directly to a computer where the programming will be done. This can be through a wired connection such as USB or JTAG, or even wirelessly in some cases.

3. Programming: The binary file is transferred to the microcontroller’s memory. This process can vary depending on the microcontroller and the programming method used.

4. Verification: After the code is transferred, it’s common to verify that the programming was successful by checking if the binary file on the microcontroller matches the original.

5. Debugging: If the circuit board doesn’t operate as expected, debugging tools are used to step through the code and hardware operation to find and fix issues.

Quick Turn PCB Prototypes and Fast PCB Prototyping Service

For many developers, the ability to quickly iterate on design and function is crucial. Quick turn PCB prototypes and fast PCB prototyping services offered by PCB manufacturers allow for rapid testing and development of circuit boards. This agility is essential for programming and reprogramming boards during the development phase to ensure the final product functions correctly.

Conclusion

Programming a circuit board is a multifaceted process that requires a seamless integration of hardware design, assembly, and software development. The expertise of PCB manufacturers and assemblers is vital in creating a board that accurately responds to the programmed instructions. With the advancement of electronic hardware design and the availability of comprehensive services from PCB design to assembly, the process from concept to a fully functional device is more streamlined than ever. As technology progresses, the collaboration between hardware and software specialists continues to be the cornerstone of innovative electronic devices.