Breadboards are a staple in electronic circuit building, offering flexibility and ease of use for both beginners and professionals. However, one of the most critical aspects of working with breadboards is selecting the right wires. The wires you choose can impact not only the functionality of your circuit but also its longevity and ease of assembly. This guide explores the different types of wires you can use for breadboard wiring, discussing their advantages, disadvantages, and suitability for various projects. Whether you’re a student constantly changing circuits or a professional testing more advanced designs, the right wire can make all the difference.

Solid Core Wires (Single-Strand Wires)

One of the most common types of wires used for breadboard wiring is the solid core wire, also known as single-strand wire. These wires come in a variety of colors and lengths, making them easy to adapt to different circuit layouts.

Different Colors of Solid Core Wires for Breadboards

Advantages:

· Affordable: Solid core wires are inexpensive. For example, a 25-foot roll of wire typically costs just a few dollars.

· Color Variety: With multiple colors available, it becomes easier to organize circuits by assigning different colors to different connections (e.g., power, ground, signal). This makes your circuit cleaner and more intuitive to troubleshoot.

· Custom Lengths: You can cut the wire to any length you need, giving you complete control over the layout of your breadboard. This flexibility is essential for more complex projects where wires need to be just the right length.

Disadvantages:

· Time-Consuming: Using solid core wire requires you to cut and strip the insulation before each use, which can slow down the assembly of your circuit.

· Fragility: Solid core wires tend to break after repeated bending, particularly where the wire is inserted into the breadboard. This can be frustrating, especially if a piece of wire snaps off inside the breadboard hole, making it difficult to remove.

Pre-Cut Wires

Many breadboards come with pre-cut wires, often packaged in sets of various lengths and colors. Some of these wires are even tinned at the ends to reduce contact resistance, making them more reliable.

Pre-Cut Wires in Storage Box

Advantages:

· Multiple Lengths: Pre-cut wires are available in various lengths, typically between 8 to 9 different sizes, allowing for versatile use in different breadboard layouts.

· Tinned Ends: The ends of pre-cut wires are often tinned with solder, which reduces contact resistance and enhances durability.

· Storage: These wires are usually sold in convenient plastic boxes, making it easier to store and organize them for future use.

Disadvantages:

· Color Confusion: Pre-cut wires are often color-coded based on length rather than function. This can make it difficult to distinguish between, for example, power and ground lines.

· Cost: Pre-cut wires tend to be more expensive than buying solid core wire in bulk.

· Fragility: Like solid core wires, pre-cut wires can also be prone to breaking after repeated use, especially when inserted and removed multiple times.

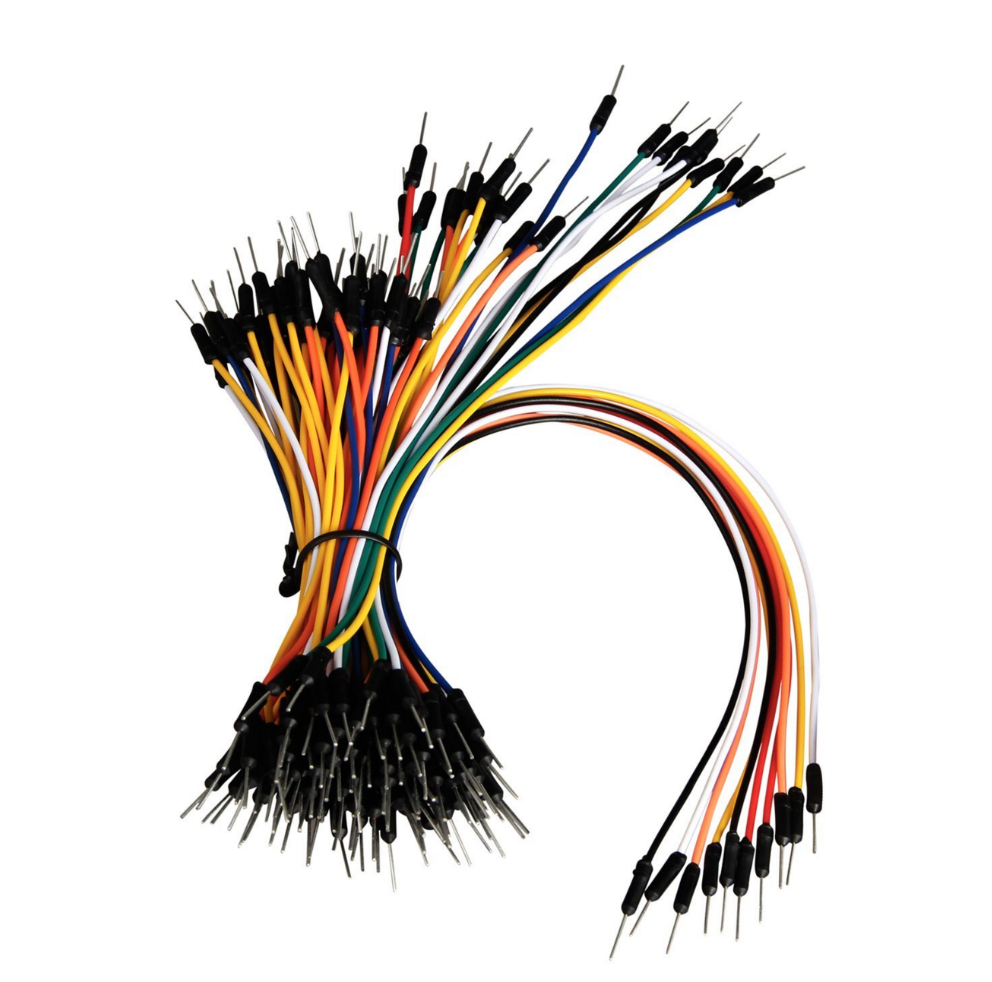

Dupont Wires (Jumper Wires)

Dupont wires are another popular choice, particularly among students and hobbyists. These wires have special connectors at both ends, making them easy to insert into and remove from breadboards. Dupont wires are often sold in a variety of colors and configurations, such as male-to-male, female-to-female, or male-to-female connections.

Advantages:

· Durability: Dupont wires are much more durable than solid core wires. Their flexible connectors are less likely to break off inside the breadboard, reducing frustration during circuit assembly.

· Flexibility: Unlike solid core wires, Dupont wires contain multiple strands of metal inside the insulation, making them far more flexible. This makes them easier to work with, especially for circuits that require frequent modifications.

· Color Variety: Dupont wires come in a wide range of colors, making it easy to keep your circuit organized and visually clear.

Disadvantages:

· Limited Length Options: Dupont wires are often only available in a few standard lengths, which can result in excess wiring cluttering your breadboard.

· Higher Cost: Compared to other types of wires, Dupont wires are relatively expensive, which might deter users from buying multiple sets.

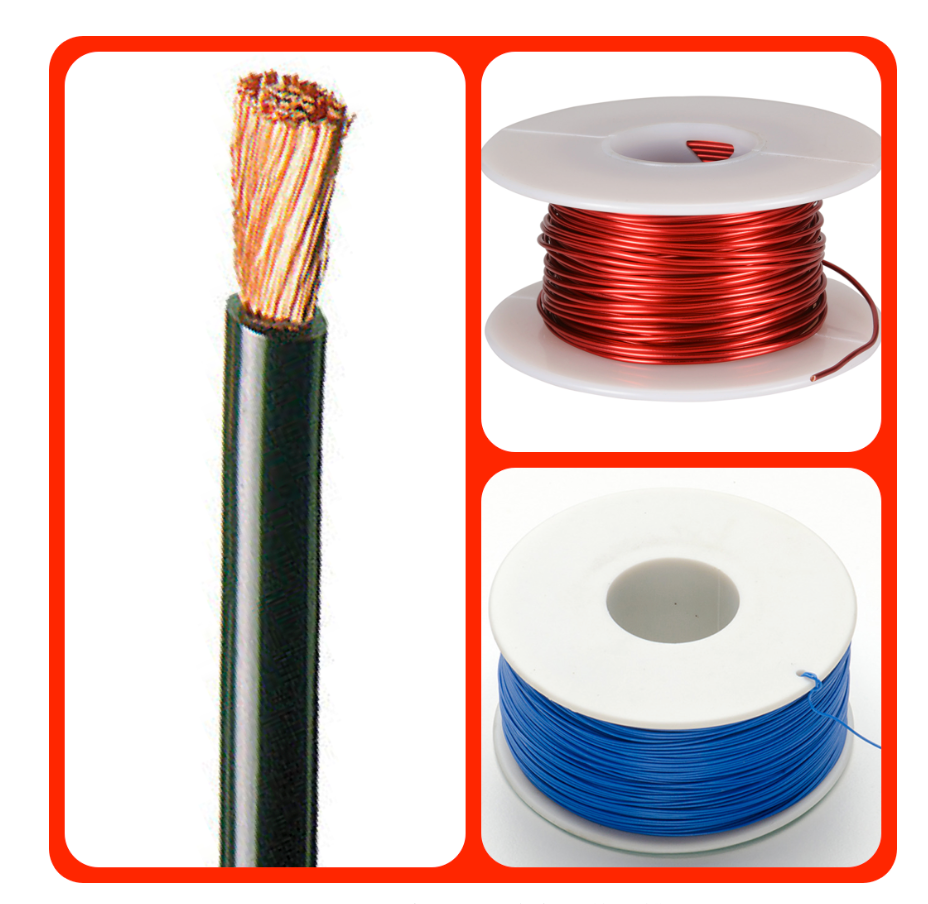

Wires to Avoid on Breadboards

There are some types of wires that should be avoided when working with breadboards. These wires may seem suitable at first glance, but they tend to cause more problems than they solve.

Wires to Avoid for Breadboard Use

· Multi-Strand Wires: These wires consist of multiple thin strands twisted together. While they are flexible and durable, the individual strands can easily fray, making them difficult to insert into breadboard holes. Stray strands can also lead to shorts and other circuit issues.

· Magnet Wire (Enamel-Coated Wire): This wire is used primarily in inductors and electromagnets and is coated with an enamel insulation that is difficult to remove. It is not practical for breadboard use due to the extra effort required to prepare the wire for insertion.

· Thin Wires: Wires that are too thin are difficult to strip and prone to breaking. They are also likely to fall out of the breadboard, causing unreliable connections.

Conclusion

Selecting the right wires for breadboard use is crucial to ensuring a well-organized and reliable circuit. For temporary circuits or projects requiring frequent modifications, Dupont wires offer the durability and flexibility needed. For more permanent or professional setups, solid core wires provide stability, despite the extra preparation time. Ultimately, the best wire choice depends on your project’s needs, balancing factors such as cost, durability, and ease of use.

For those working on more advanced or large-scale projects, including PCBA manufacturing, it’s essential to consider additional factors like printed circuit board (PCB) design and assembly. Whether you’re developing a custom prototype or looking for turnkey PCB assembly services, choosing the right PCBA manufacturer can make a big difference in both cost and efficiency. Companies like Arisentec provide a range of services, from PCBA prototyping service to full-scale manufacturing, ensuring high-quality production for applications like smart home PCB systems and LED light PCBs.

In the end, your choice of components—whether it’s wires or entire PCBs—will influence the overall success of your project. Be sure to select trusted suppliers and manufacturers for the best results.

*This article is sourced from the Jiangxi Electronics and Circuit Industry Association.*

Choosing the Right Wires for Breadboard Wiring: A Comprehensive Guide

Breadboards are a staple in electronic circuit building, offering flexibility and ease of use for both beginners and professionals. However, one of the most critical aspects of working with breadboards is selecting the right wires. The wires you choose can impact not only the functionality of your circuit but also its longevity and ease of…

How to Improve Heat Dissipation in PCB Design

Introduction As modern electronic devices become more complex and power-dense, heat dissipation has emerged as a critical factor that directly impacts device performance and reliability. Excessive junction temperatures in electronic systems can shorten the lifespan of components and lead to system failure. Thus, optimizing the PCB (Printed Circuit Board) design to improve heat dissipation is…

Manufacturing Process of Multilayer PCBs

Multilayer PCB manufacturing methods include the plated-through hole (PTH) and high-density interconnect (HDI) methods, both achieved by combining different processes to realize the circuit board structure. Currently, the most widely used method is the PTH method, which has been developed and refined over more than half a century. The PTH method is mature in terms…